There is a significantly high number of piston ringland failures on the later model Subaru WRX and WRX STI. The goal of this article is to help you avoid becoming one of them. Some of these may seem like common sense to most, but for many younger or first time turbo car owners it may be new.

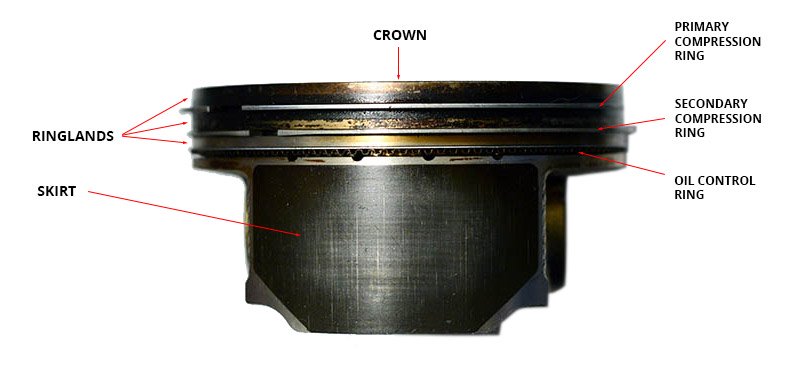

The ringlands are the areas of the piston adjacent to the rings and ring grooves. All of the turbo 2.5L (EJ25) and 2.0L (EJ20 / FA20) pistons feature three ringlands which accomodate the two compression rings and one oil control ring.

The first ringland (aka top land) is located between the top of the piston (known as a crown or deck) and the primary compression ring. This ring seals out the majority of the heat and combustion gases from the crankcase.

The second ringland bridges the primary and secondary compression ring. The secondary ring seals out any gasses that get past the primary ring. Its unique shape also scrapes any oil that has gotten past the third ring (aka the oil control ring) off the cylinder walls.

The third ringland bridges the secondary and third ring, the oil control ring. The oil control ring is shaped completely different from the two compression rings. The ring's design scrapes oil from the cylinder walls and forces it into oiling holes and onward to the wrist pins.

Ringland failure is when excessive heat and pressure cause the ringland to fracture. The fractured ringland no longer supports the ring properly which allows combustion gasses to blow down into the sump, often pressurizing it. This in turn causes excessive oil burn-off from a combination of blowing it through the PCV system, burning it off the cylinder wall(s), and flashing off oil in the crankcase / sump.

Detonation is the mechanism that physically damages the pistons. Anything that promotes detonation such as low octane fuel, lack of proper tuning, and prolonged hard driving can potentially cause piston ringland failure.

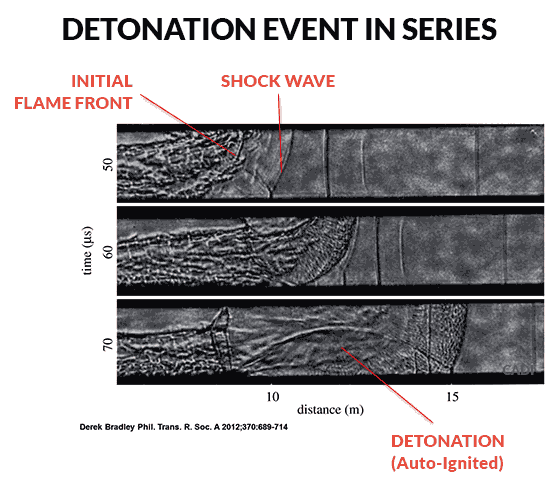

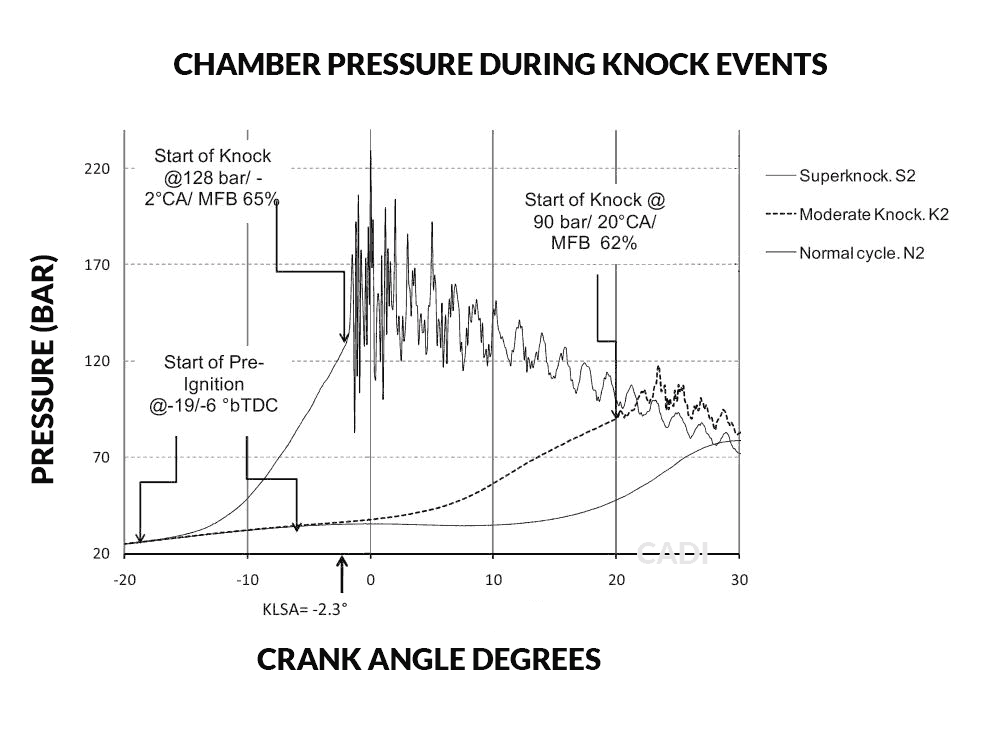

Detonation is when the mixture auto-ignites and forms an additional flame front in the combustion chamber. This spontaneous ignition causes the flame fronts to slam into each other and produce a pressure spike well in excess of typical combustion. This pressure wave will continue to bounce off of the cylinder walls producing a strong cyclical load.

This "jackhammering" effect either shatters the ringland immediately, or contributes to a future failure from fatigue and/or overstress. This is due to the material's inability to absorb energy through deformation or flexure (ductile behaviors), in conjunction with the rapid onset of stress due to detonation.

Piston ring gap is also a growing concern with the more recent motors. The gap is tight from the factory which makes the primary compression ring prone to binding. Binding occurs when the ring heats up and runs out of expansion room. The ring then flexs and puts a point load on the piston ringlands. Given enough stress, this can crack the ringland outright, or contribute to its failure.

Weak? ... No

Brittle? ... Absolutely

While detonation is what damages the pistons, it's important to know that the EJ20 (EJ207 / EJ205), EJ25 (EJ255 / EJ257), and FA20 all have brittle pistons due to Subaru's material and design choices. The pistons are cast hypereutectic aluminum-silicon (Al-Si) alloy; a very common material choice for modern engines. Well proven engines like the 2JZGTE, 4G63, SR20DET, RB26DETT, LSX, K-Series, and others all use Al-Si alloys.

However, Al-Si alloys can vary depending on the percentage of silicon in the material. Subaru has opted for a "hypereutectic" alloy which is a high-silicon (12+%) mix. This makes the piston have extremely low thermal expansion, and allows Subaru to run an extremely tight piston-to-bore clearance. The high-silicon content also makes the piston considerably stronger than aluminum itself. For example, a 9% silicon (by wt.) alloy has a 14% higher yield strength than a 7% silicon alloy. This strength comes at a cost: fracturing.

When you take a sledgehammer and hit a steel hood, the steel simply deforms under the pressure of the hammer strike, leaving a dent. When you take the same sledgehammer and hit a window, the block shatters the window. That is because the window material reacts to the strike by fracturing rather than deforming. When you add silicon to aluminum it acts more and more like the window glass.

Detonation energy ironically enough, acts like the hammer.

You can read more about detonation here: Detonation and Knock

There's a long list of things that can lead to detonation in a spark-ignition gasoline motor, but here's a few things that stand out on Subarus.

Intakes, downpipes, exhaust manifolds, and other common modifications require adjustments to the factory tune in order to run properly. Subaru built in logic to the ECU to make adjustments for altitude, pump fuels (i.e. 91 ACN vs. 93), climate, but it's not well suited to accomodating for most modifications. Intakes are an extremely common modification that requires specific adjustments to the MAF calibration tables in order to properly meter the incoming airflow. This is because aftermarket intakes affect the airflow through the MAF housing.

Each intake will have it's own MAF calibration. This is why Cobb has a tune for their SF intake and the AEM intake.

Pretty obvious that a "bad" tune is not ideal. This is why you should research tuners and make sure they not only have experience with tuning Subarus, but that you are also doing your part to give them accurate feedback and data, quickly implementing new maps and fixes, and following their directives closely. People can be quick to incorrectly blame a tune for their own mistakes.

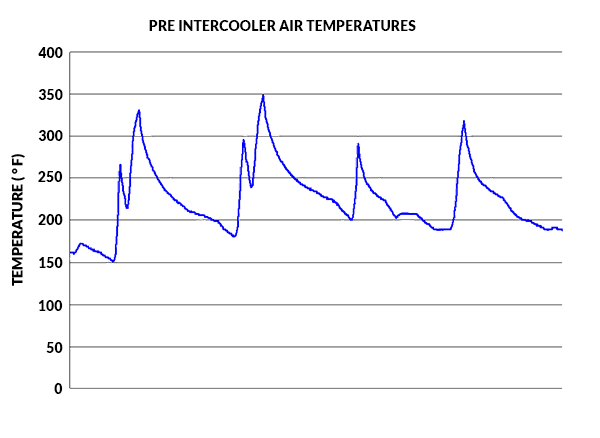

A stock STI on a cool day will produce boosted air temperatures around 230°F (110°C) at 14 PSI, but on a hot day that number increases to 310°F (154°C) at 14 PSI. For an STI running increased boost this figure can climb as high as 360°F (182°C)!

Because of the high temps, the intercooler will steadily get warmer as you accelerate which reduces its ability to cool the airflow; known as "heat soak." The net result is higher inlet temperatures into the cylinders, less power from a reduction in air density, and a greater chance of detonation.

This is an even bigger problem on vehicles equipped with smaller OEM intercoolers found on the non-STI cars. They have considerably less mass and surface area which means they will heat up faster and shed that heat much slower.

Subaru located the air temp sensor in the airbox along with the mass airflow sensor (MAF). This is a common practice in MAF equipped engines, but it is extremely limiting from a tuning perspective because it only allows for corrections based on the pre-turbo air temperature. The ECU is essentially blind to the actual air temps.

In the South on a warm summer day it's common for intake temperatures to be north of 120°F (48°C), especially with more open-air intake designs like Cobb's SF intake. This in turn greatly increases the boosted air temperatures and can lead to detonation. Fortunately, this hot air is measured and can be accounted for in the tune, but as noted above, this only goes so far.

The only fuel you should ever put in a turbo Subaru is the highest commonly available octane fuel in your area, period, end-of-discussion. For the US, Canada, and Mexico this is going to be 91 - 94 octane gasoline (AKI Method), or a gasoline:alcohol blend (known as "flex fuel") such as E85. Any fuel containing more than 10% Ethanol by volume (aka "E10") will need a tune to run properly.

Use 95 - 100 octane gasoline for Europe, Japan, and other countries that use the RON (Research Octane Number) method for rating fuel.

Make sure tunes for "Premium Fuel" are for the specific octane and blend in your area!

Oil vapor in the combustion chamber makes detonation and pre-ignition more likely. The two most common sources of oil vapor are the turbocharger and the positive crankcase ventilation system (PCV). The PCV system allows the pressure built up in the crankcase to be drawn through the intake. Turbochargers are much less likely to cause oil vapor issues, but they can if the shaft seals leak due to old age or wear.

Even the STI is not configured to be driven hard for a very long time. That means the other turbo Subarus are even less prepared. It's important to know the limits of your vehicle in terms of thermal load, and most of that is going to be based on how you drive the car. Driving it like you are on the last 5 minutes of Le Mans with an Evo on your bumper is incredibly fun, but also incredibly inviting to detonation.

A clear example of lugging an engine is driving down the highway in 5th (5MT) or 6th (6MT) and flooring it with the engine around 2,000 to 3,000 RPM.

This builds a lot of load on the engine and also utilizes portions of the ECU maps that may or may not be ideally tuned for it. So much so that Subaru and other OEMs even warn against it in the owner's manual. Pre-ignition and detonation are more likely to occur at lower RPMs due to the larger window of time given by the slower piston speeds. Although, generally air temperatures are much lower at these engine RPMs which helps to reduce the chance for detonation.

The FA20 and other direct-injection turbo (DIT) engines have had a history of LSPI, low speed pre-ignition. The prevailing thought is that when the fuel is injected into the chamber it thins any engine oil that may be on the cylinder walls. This allows the oil / fuel mix to collect in the crevice between the piston crown and cylinder wall. Eventually, an oil laden droplet ends up in the chamber where it auto-ignites and causes a hardcore detonation event very early in the combustion process. This is extremely destructive and will shatter pistons, bend rods, and eat up bearings.

As noted above, you need to effectively prevent as much detonation as possible. I give you the "Six Commandments of Turbo Subarus."

The items I'm about to mention are not exhaustive, nor are they absolutely necessary to have a reliable engine. As I've said before, this is a dynamic issue that all stems from detonation. Thus these recommendations are centered around preventing detonation, or otherwise improving engine durability.

I'm not going to tell you not to have fun. You bought the car for a reason. Just think of your turbo Subaru as a horse. You need to let the horse warm up a bit before you run it hard. You don't want to run the horse too long because it will get tired. If you push the horse beyond its limit, it will keel over and die. After you run your horse, let it cool down and rest before you run it hard again.

Horses are expensive ... and so is a new shortblock.

I strongly recommend buying a Cobb AccessPort V3.

Even if you don't intend to run a tune or modify the engine. The ability to log and view parameters such as knock, ignition trims, boost, and intake air temperatures is vital information for the driver. The V3 model is far superior to the V2 when it comes to being able to view real-time data. Not only can you see more real-time parameters, but the logging also has higher resolution.

If you can find another solution for less, then go for it! You need to be able to quickly see the data while you are driving or program it to alert you when it exceeds a pre-set limit. Make sure that functionality is part of your solution. Logging, re-call, peak/hold, etc. are all good features also. In fact, contact me if you have a solution like this and I can feature it here.

Power does not equate to reliability. It is not validation of skill on behalf of the tuner. In fact, making power is one of the easiest tasks for a tuner. Things like MAF scaling, knock response, individual trims, and AVCS mapping can make significant differences in reliability. A good tuner knows how each component and signal can be utilized to a desired result.

In the 90s the ECUs ran very simple fuel and ignition maps compared to modern vehicles. Subaru's ECU uses sensor data to determine what values to pull from the numerous tables (boost control, timing, fueling, etc.) to affect the final fuel and ignition outputs. This complexity necessitates familiarity, experience, and a solid theory background. It's not as forgiving or friendly to novices, but at the same time, is very useful for professionals.

Get a custom tune for your specific vehicle, needs, and from a reputable tuner.

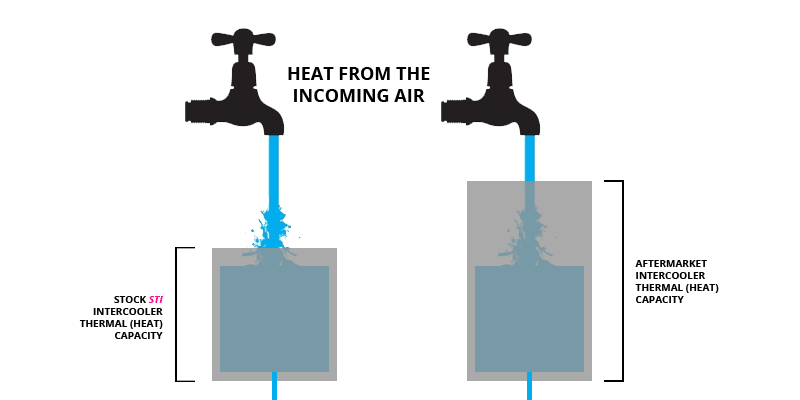

Hands down one of the best mods you can do to any turbocharged vehicle is to upgrade the intercooler. While the stock STI cooler is pretty efficient, it lacks the thermal mass of aftermarket intercoolers.

To help visualize this concept, think of the turbo as a faucet, the intercooler as a bucket, and water represents heat. The stock intercooler is a 1-gallon bucket and an aftermarket intercooler is a 1.5-gallon bucket. Now cut a hole in the bottom of the buckets to represent the ability of the intercooler to cool the airflow. The slightly more efficient STI intercooler has a 1" hole in the bottom while the aftermarket intercooler has a 0.97" hole in the bottom. The small gain in peak efficiency (3%) is dwarfed by the 50% gain in capacity.

In the above visual, the stock STI intercooler is heat soaked and its ability to cool the incoming air is greatly diminished. The aftermarket intercooler is still capable of cooling the airflow due to its increased thermal mass (capacity).

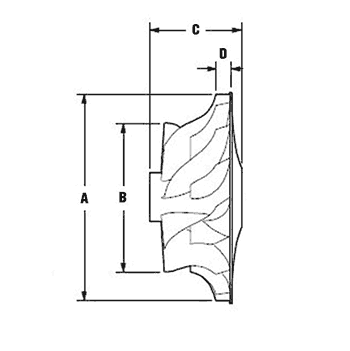

Believe it or not, but a bigger turbocharger is a great upgrade for engine durability. For Subarus running 18+ PSI, the larger compressor wheel and housing will produce the same boost pressure at a lower temperature. The bigger turbine and turbine housing also improve the ability for the engine to expel exhaust gasses. Overall it is a great upgrade for any Subaru running more than stock boost pressure.

This doesn't mean it's safe to run 30 PSI with a big turbo. Your shit will explode.

To reiterate, it's better to run a bigger, more efficient turbocharger at the same, elevated boost pressure from an engine durability perspective.

This is a no-brainer, but one of the best things you can do is run the highest octane fuel in your area. Go with a premium grade gasoline in the 91 - 94 AKI octane range (95 - 100 RON) from a reputable source like Shell, Chevron, etc.

Make sure you are running the proper octane fuel for your tune as well. If you are traveling and come across a 91 octane pump and you are tuned for 93 octane, then you should either swap maps, or consider applying global ignition retard.

Ethanol and methanol are far superior fuels for highly boosted engines. They have a profound effect on cooling the incoming airflow due to their thermal properties. This, combined with a low sensitivity makes them highly detonation resistant. This in turn allows for considerably more ignition timing advance, resulting in greatly increased torque and horsepower output at the same boost pressure.

There are some downsides to E85 and other alcohol-based fuels, especially methanol. Be sure to read up on the differences.

This is not a very fun recommendation, but none-the-less if you run less boost, you will see less chance for detonation because of lowered IATs and thermal load.

The easiest way to do this is simply to run the stock airbox. The airbox is sealed, constructed of an insulating material (plastic), works perfectly with the MAF, and it is designed to pull airflow from the grill duct.

Aftermarket intakes like the Cobb SF will increase the intake air temps, even with the optional airbox and careful attention to sealing it. Some aftermarket intakes, like Grimmspeed, draw air from outside the engine bay which greatly helps to lower intake air temps.

You can further reduce underhood temperatures with properly vented hoods, thermal coatings on exhaust components, a turbo blanket, and thermal tape.

Backpressure and reduced port flow velocity will cause the cylinders to run hotter. Improving the exhaust flow by reducing backpressure will help the engine to effectively expel hot gasses. This is commonly done with an aftermarket 3" downpipe and cat-back exhaust.

It's also important to eliminate momentary backpressure created by an unequal-length exhaust manifold. An equal-length manifold ensures that there is an equal opportunity for each cylinder to blow down exhaust gasses regardless of the RPM. An unequal-length exhaust manifold will encounter conflicts throughout the RPM range where two exhaust pulses are colliding or negatively interacting. An equal-length manifold prevents a pair of cylinders from running hotter than the others.

Read more on exhaust manifold design here: Equal Length vs. Unequal Length (EL / UEL) Subaru Manifolds Explained

You can keep the entire intake tract cleaner and eliminate oil vapor ingestion by running a good catch can or air-oil separator (AOS). This is a good practice for any engine, but horizontal engines in particular are notorious for having a lot of oily blow-by and breather flow. Forced induction also increases the need for these systems.

If given a choice, I prefer a catch can setup to an AOS. The primary benefit of a catch can is being able to measure the amount of oil that is being passed through. Sudden unexpected increases in oil volume can signal issues with ring seal. A nice secondary benefit is not having the added complexity and weight of an AOS setup that utilizes a warming loop to avoid water contamination of the oil.

Downshift rather than building a bunch of boost in a high gear. It's fun and it will let the engine operate at a more optimal RPM. This is particularly important for the FA20 crowd.

Absolutely not. Turbo engines from all manufacturers have suffered similar failures. However, 2.5L Turbo (EJ25x) Subarus are particularly susceptable to failure because of their piston design and material, owner / driver choices, and the high-boost platform itself.

Thank you for the help and contributions you all made to this article!

Detonation and Knock Explained

Subaru Equal vs. Unequal Length Exhaust Manifolds

We are constantly looking for new content ideas and feedback from the community. Head over to our contact page and send us an email with your ideas, comments, or questions.

Join our email list to be notified when we release new content.

We respect your inbox and send only 1 - 4 emails per month.

We will never spam, sell, or do annoying things with it ... ever.